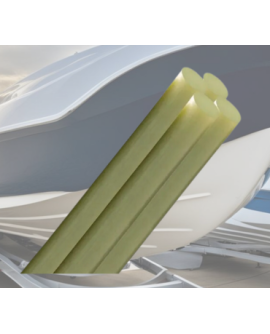

Epoxy Resin vs. Polyester Resin: Comparing the Strengths in Fiberglass Applications

29/04/2024

Epoxy Resin: Superior Adhesion and Durability

Epoxy resin is known for its outstanding adhesion and mechanical properties, making it a preferred choice in many fiberglass applications. Here are some key strengths of epoxy resin:

1. Superior Adhesion

Epoxy resin offers exceptional adhesion to a variety of surfaces, including fiberglass, wood, and metal. This strong bonding capability ensures a durable and long-lasting fiberglass structure.

2. High Strength and Stiffness

Epoxy resin provides high strength and stiffness, resulting in robust and resilient fiberglass components. This makes it ideal for applications that require structural integrity and load-bearing capacity.

3. Low Shrinkage

Epoxy resin exhibits low shrinkage during the curing process, which helps maintain the precise shape and dimensions of the fiberglass product. This minimizes the risk of warping or distortion in the final product.

4. Chemical Resistance

Epoxy resin has excellent chemical resistance, making it suitable for fiberglass applications exposed to harsh chemicals, solvents, or corrosive environments.

5. Better Moisture Resistance

Epoxy resin offers superior moisture resistance compared to polyester resin, providing better protection against water damage and making it a strong choice for marine applications.

Polyester Resin: Cost-Effective and Versatile

Polyester resin is a versatile and cost-effective option commonly used in fiberglass applications. Here are some of its strengths:

1. Lower Cost

One of the main advantages of polyester resin is its lower cost compared to epoxy resin. This makes it an attractive choice for projects with budget constraints or where cost savings are a priority.

2. Fast Curing Time

Polyester resin has a faster curing time than epoxy resin, allowing for quicker production and shorter turnaround times. This can be advantageous for large-scale projects or when time is a critical factor.

3. UV Resistance

Polyester resin offers good resistance to UV rays, which can help protect the fiberglass product from sun damage and degradation over time.

4. Wide Availability

Polyester resin is widely available and can be easily sourced, making it a convenient choice for various fiberglass projects.

Conclusion

Both epoxy resin and polyester resin have strengths that make them suitable for different fiberglass applications. Epoxy resin excels in adhesion, strength, low shrinkage, chemical resistance, and moisture resistance, making it ideal for projects that require durability and resilience. On the other hand, polyester resin offers cost-effective versatility, fast curing time, UV resistance, and wide availability.

When choosing between epoxy resin and polyester resin for your fiberglass project, consider your specific needs, budget, and desired performance characteristics. Ultimately, the best choice depends on the particular requirements of your application and the priorities of your project.